Mist eliminators, also known as demisters or mist filters, are widely used in various industries for several important reasons:

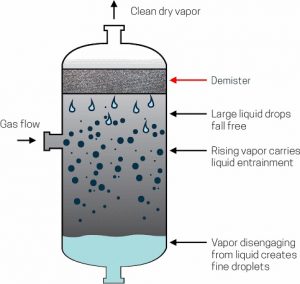

Removal of Liquid Droplets: Mist eliminators are designed to capture and remove liquid droplets from gas streams. These droplets can be formed due to processes such as condensation, or evaporation. By removing liquid mist, mist eliminators help improve the quality and cleanliness of the gas stream.

Protection of Downstream Equipment: In many industrial processes, downstream equipment such as compressors, turbines, heat exchangers, or filters can be sensitive to liquid droplets. The presence of liquid mist in the gas stream can cause damage, corrosion, fouling, or reduced efficiency of these equipment. Mist eliminators prevent the entry of liquid droplets, safeguarding the performance and longevity of downstream components.

Product Recovery: In some processes, mist eliminators can be used to recover valuable liquid droplets that may contain valuable products or chemicals. By capturing these droplets, mist eliminators allow for their separation and subsequent recovery, reducing product loss and improving overall process efficiency.

Mist eliminators can be found in various industries, including chemical processing, oil and gas production, power generation, wastewater treatment, pharmaceuticals, food and beverage, and many others. They are available in different designs, such as mesh pads, vane-type separators, fiber bed filters, or cyclones, to suit specific process requirements.