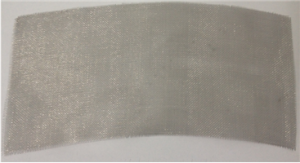

Nickel wire mesh is particularly effective for the anode and cathode for fuel cells and batteries. Nickel woven wire mesh are usually made with a controlled thickness,can be applied to a wide variety of fuel cell development, but most often as a current collector and for anode and cathode construction.

Nickel wire mesh material

Nickel woven wire mesh is manufactured from nickel wire with high purity not less than 99%.

The wire mesh is commonly made from nickel grade N2 N4 N6.

Main features

Excellent chemical stability and anti-corrosion resistance

High electrical conductivity

high porosity,

light weight and good flexibility

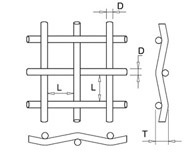

Nickel Mesh Weave Types : Plain Weave

Nickel Mesh Sizes:

Mesh: 20mesh to 60mesh

Roll width: 20mm to 500mm

Roll length: 30m to 300m

Our nickel mesh can be customized upon request, such as the thickness/width,pore size,pore density etc.

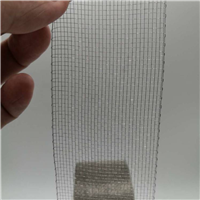

Mesh Edge We Produce

It can be provided as discs or cut into mesh tapes. The mesh tapes are supplied at extremely small width up to 20mm. In addition, we designed special machines to produce the finish edge mesh. The finish edge will increase the mesh stability and provide a safety edge for handling. And It will also protect the battery separator.

Supply Form

A multitude of mesh supply forms are available, it includes, but not limit to tapes, sheets, discs etc.

Application

anodes and cathodes in fuel cells

alkaline fuel cell

anode of lithium-metal batteries

Nickel–Metal Hydride HEV Batteries

Rechargeable nickel metal hydride (NiMH) batteries

Porous transport layer for water electrolyzers

Fuel cell gas diffusion layer

Electrodes for alkaline water electrolyzers

nickel–metal hydride (NiMH)

nickel–cadmium (NiCd) batteries.

solar cell and catalysis applications

Leave a Reply