Stainless steel wire screen is made in rolls on a loom. It consists of a warp and weft wire and the openings can be made in square or rectangle shapes .This wire diameter and mesh with ratio reasonable, therefore weave structure is very strong. After 13 whole weaving process, so that the mesh surface flatness better

Raw Materials

Our stainless steel wire screen is generally of stainless steel 304, 304L,316, 316L etc.

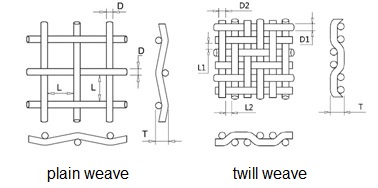

woven mesh types and sizes

| Plain weave stainless steel wire mesh | from 1mesh to 300mesh,including1mesh,2mesh, 3mesh, 4mesh,5mesh,6mesh,8mesh,10mesh,12mesh,14mesh,16mesh,18mesh,20mesh,22mesh,24mesh,30mesh,40mesh,50mesh,60mesh,80mesh,100mesh,120mesh,150mesh,180mesh,200mesh,250mesh,300mesh |

| Twill weave stainless steel wire mesh | from 40mesh to 635mesh, including 40mesh,50mesh,60mesh,80mesh,100mesh,120mesh,150mesh,180mesh,200mesh,250mesh,300mesh,325mesh,400mesh,500mesh,600mesh,635mesh |

Characteristics

- Square hole,warp wire and weft wire are of equal size.

- Accurate in mesh size,high flow rate.

- High efficient screening,good stability,high opening rate,Low pressure loss.

- Flat surface,wear-resistant,good air permeability,firm in structure,easy to clean.

Stainless Steel Wire Mesh Application

- Architectural & decorative industries

- EMI & RFI shielding industries

- Filtration & oil industries

- Petrochemical & chemical industries

- Battery industries

- Food processing industries

- Plastic & rubber extrusion industries

- Screen printing industries

- Fly screen & security mesh

- Pharmaceutical industries