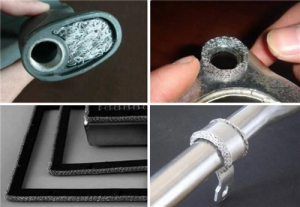

Compressed mesh gaskets provide excellent EMI shielding and grounding properties. Fabricated by seamlessly die compressing knitted wire mesh into a wide range of shapes and varied resiliencies. An optional crimping process of the knitted mesh prior to die compressing can add further resiliency.

Compressed mesh gaskets are designed for applications requiring small round or rectangular EMI seals for applications in waveguide choke flanges, shafts or small housings. Due to their high compression set, they are not recommended where mating joints must be opened and closed. The gaskets are held in place by sidewall friction in tight slots/grooves or slipped over a shaft. Since they are compressed, the gaskets need no allowance for material flow or lateral deflection. Width and material permitting, bolt holes, recessed areas, corner radii and other features can be formed in the gasket wall.

Compressed mesh gaskets can be used for the following requirements:

- Vibration dampening and shock absorption

- Air/liquid filtration and particle retention

- Acoustic noise reduction

- Mechanical spacers, mounts, support parts and flexible joint seals

- Flame arrestors and heat seals