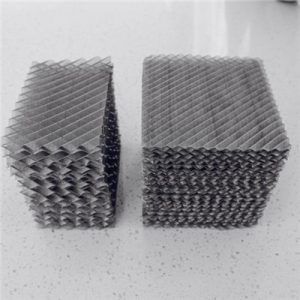

Structured packing also known as corrugated sheet structured packing and gauze packing, it is a kind of tower packing. The structured packing is constructed from multilayer corrugated sheets of stainless steel wire mesh (wire gauze) or perforated sheets. The special open honeycomb structure with inclined flow channels has resulted a large filtration surface area, and lower pressure drop.

Structured packing is manufactured in a wide range of sizes by varying the crimp altitude. Packing surface ranges from 100 m²/m³ (lowest efficiency, highest capacity) to 750 m²/m³ (highest efficiency, lowest capacity).

Characteristics

- High number of theoretical plates, large flux and low pressure drop

- Good performance with low working load

- Large operation elasticity

- No obvious amplification effect

- Fulfilling the requirements of precision, large and high vacuum distillation units

Main applications

- Monomers from plastics

- Fatty acids, fatty alcohols, fatty acid esters

- Mono, di, tri, and tetra-ethylene glycols

- Pharmaceutical products

- Fragrances

- Separations of mixed isomers

- Fine chemicals