The fibre bed mist eliminators also known as candle filters and fiber bed filters, they are made of a variety of fibre diameters and lengths which are packed between two concentric cylindrical screens with a top flange and a bottom drain plate.These fiber bed filters are used by a broad range of industries, from sulfuric acid to asphalt manufacturing, plastic extrusion, metalworking and many more.

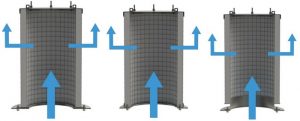

The main function of filtering mist eliminators is elimination of mist out of air or gas flow using the method of Brownian diffusion trapping with relatively low velocity of gas flow (less than 0.2 m/sec). When gas flows through the layers of extra fine fiber, small particles of mist interact with gas molecules around, which makes these particles move in different directions, to and from the fibers, which results in coalescence of trapped liquid drops that contact the fiber surfaces and formation of liquid film. The drops, becoming larger, trickle down out of fiber layers in the form of a trickle or large drops which move around within the layer on the backside of the filtering element, and finally flow down into the water seal due to the force of gravity and increase of gas flow and capillary forces. As usual, in such a case no other mechanical effect on filtering layers is required, i.e. filters operate under constant resistance in steady-state self-recovery (self-clearing) mode.

Materials

The packed of fiber beds are available in

- Special glass fiber

- Polypropylene fiber

- Carbon fiber

- The cages using a wide variety of materials

- Stainless steel

- Carbon steel

- FRP

- Polypropylene

- Thermal-set plastics

Benefits

- Increased surface area

- Remove mist and small droplets

- Prevent contamination of the process

- Recover a useful product

- Protect valuable downstream equipment

- Reduce maintenance costs

- Minimize environmental impact