We supply a variety of sieve bend screen to suit a wide range of vibrating working conditions in the coal and mineral processing industries. The wedge wire screens has good mechanical properties, high strength, rigidity and load capacity, can be able to withstand the high acceleration forces associated with vibration.

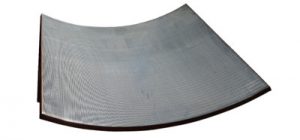

Wedge wire sieve bend screen is manufactured by wrapping and welding V type profile wires cylindrically around support rods, then be made into panel screen through cutting and radian processing. The screen curved in profile and operates that more effectively than flat screen panels in the same application. As the flows over the inclined screen surface, V shape profile wires provides a sequence of edges, thus enable its leading edge to cut the flow and collect liquid and smaller solid particles in the processing. The much larger particles will remaining on the surface, eventually slide down to the bottom of the screen.

Benefits

- continuous separation

- no maintenance costs

- capable of handling large concentration of solids

- unique ‘shear’ movement

- simple interchange ability of screen plates to adapt to changes in process conditions

- low investment

- low noise

- minimal operation costs

- various construction as standard

- static connections on vibration screen