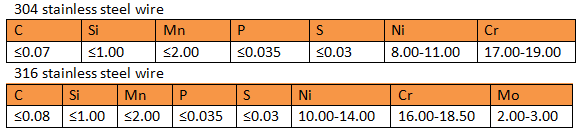

304 refers to “18-8” ( 18% chromium, 8% nickel ). 304 is the basic stainless alloy commonly applied for woven wire cloth. It withstands outdoor exposure without rusting and resists oxidation at an elevated temperature up to 800 °Cs. 304 is used in all industrial, commercial and domestic fields because of its good corrosion and heat resisting properties.

316 has better resistance to pitting corrosion than the other chromium-nickel stainless steels where brines, sulphur-bearing water or halogen salts, such as chlorides are present. A valuable property of 316 is high creep strength at elevated Temperatures. 316 also possesses excellent mechanical and corrosion properties at sub-zero temperatures. Other mechanical properties and fabricating characteristics are similar to 304. Wire cloth woven of 316 has extensive use in chemical processing when better corrosion resistance is required than the regular chromium-nickel types.

The stainless steel grade that should be used depends on the practical application. If the mesh is going to be subjected to harsh conditions that introduce corrosive substances, 316 is more better than 304. Because of the molybdenum added to 316 stainless steel, it allows to withstand more corrosive applications.

When you use the mesh to sift non-corrosive materials, such as food particles or aggregates, 304 is better.