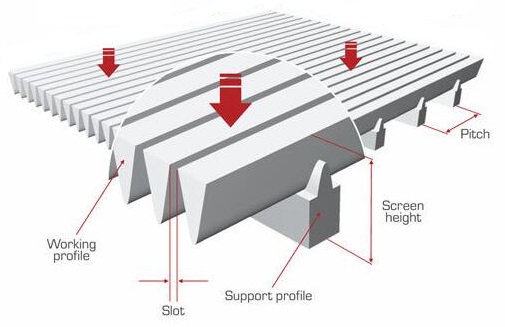

Open area rate–The percent open area of a Wedge Wire screen can be an important parameter when predicting flow capacity. Percent Open Area = ( Slot Opening / (Wire Width + Slot Opening)) x 100

Non-Clogging—Wedge Wire Screens are fabricated by cylindrically wrapping a continuous V-shaped wire around axial support rods. The uninterrupted slot formed allows for only two points of contact with particles on the screen surface to minimize clogging. This means that the maximum effective flow area and operating efficiency are maintained.

Profile Wire –Profile Wire also known as wedge wire, V-wire, Tri-wire or surface profiles, it allows a high level of precision and efficiency in screening applications. The wedge shape of Profile Wires provides a large opening (conical slots in case of V-shaped profile wires) for material to flow between the wires.Profile wires increase screening efficiency by substantially reducing blinding and pegging.

Slot Size–It means the clear distance between any two adjacent profile wires. Slot size is controlled very accurately as it forms the slot through which the filtrate flows.

Support Rod–It is also known as support profiles, onto which surface profiles are resistance welded. Support rod includes triangle wire, round bar, flat bar and wedge wire.Depending on the application, requirement and the profile wire chosen, there are a multitude of support wires available.

Support Rod Distance–It means the clear distance between any two adjacent support rods.