The sieve bend screen, also known as a DSM screen or curved screen, is a type of screening device used for solid-liquid or solid-gas separation. It is commonly used in industries such as mining, wastewater treatment, pulp and paper, and food processing. The working principle of a sieve bend screen is as follows:

Feed Introduction: The mixture of solid and liquid or solid and gas is introduced into the sieve bend screen at the feed end. This can be done through a pipe or chute, ensuring an even distribution of the material across the width of the screen.

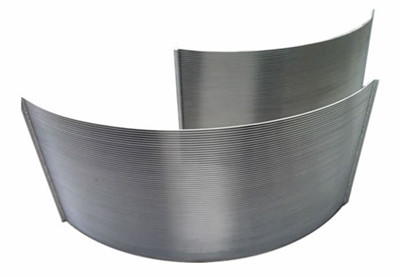

Curved Screen Surface: The sieve bend screen consists of a curved surface made of wedge-shaped wires. The wires are placed at a specific angle to create a curved surface. The angle and spacing of the wires or plates depend on the specific application and desired separation efficiency.

Particle Separation: As the mixture flows over the curved surface of the sieve bend screen, the solid particles or larger particles in the mixture come into contact with the surface. The particles that are larger than the opening or spacing of the screen surface are retained on the surface, while the smaller particles or liquid/gas can pass through the screen.

Particle Drainage: The retained particles form a thin layer or cake on the curved screen surface. The angle of the screen surface helps facilitate the drainage of liquid or gas from the retained particles. Gravity assists in the drainage process, allowing the liquid or gas to pass through the screen and separate from the retained solids.

Collection of Separated Materials: The separated liquid or gas that passes through the sieve bend screen is collected and directed to the appropriate outlet or further processing. The retained solids form a layer or cake on the screen surface and are either collected manually or removed by mechanical means, such as brushes or scrapers.

Continuous Operation: The sieve bend screen operates continuously, with the mixture being continuously fed into the screen, and the separated materials being continuously collected or discharged. The screen surface can be cleaned periodically to remove any accumulated particles or fouling that may affect the separation efficiency.

The working principle of the sieve bend screen relies on the combination of curved screen surface, particle size, and particle shape to achieve efficient separation. The larger or coarser particles are retained on the screen surface, while the smaller particles or liquid/gas pass through. The curved screen surface and gravity assist in the drainage of liquid or gas from the retained solids. This separation process enables the classification, dewatering, or clarification of various materials in industrial applications.