There are several types of sieve bend screens available, each designed to suit specific applications and separation requirements. Here are some common types of sieve bend screens:

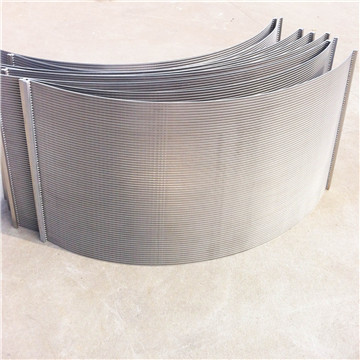

Wedge Wire Sieve Bend Screen: This type of sieve bend screen consists of wedge-shaped wires arranged in a curved profile. The wedge wires are welded or connected to support rods, creating a sturdy and durable screen surface. Wedge wire sieve bend screens are known for their high strength, excellent filtration efficiency, and resistance to clogging.

Perforated Plate Sieve Bend Screen: Perforated plate sieve bend screens feature a curved surface made of perforated plates. The plates have uniformly spaced holes or slots that allow for particle separation. This type of sieve bend screen is suitable for applications where fine or delicate particles need to be separated, as the perforations provide gentle screening.

Each type of sieve bend screen offers unique advantages and is selected based on factors such as the nature of the material to be separated, particle size distribution, flow rates, and operational conditions. Proper selection of the sieve bend screen type is essential to ensure optimal separation efficiency and long-term performance.