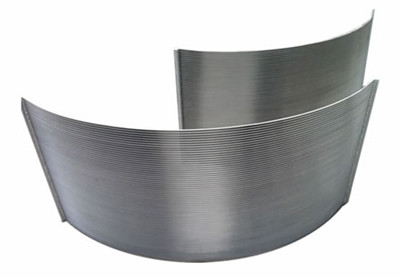

A sieve bend screen, also known as a DSM screen, is a type of curved screen used in various industries, including the pulp and paper industry. It is designed to separate solids from liquids or classify materials based on particle size.

In the pulp and paper industry, sieve bend screens are commonly used in the stock preparation process and pulp screening applications. They play a crucial role in removing unwanted debris, fibers, and contaminants from the pulp, ensuring the quality of the final paper product.

Here’s how a sieve bend screen works:

The pulp or liquid flows into the curved screen from one end and moves along the curved surface.

As the pulp flows through the screen, the slotted openings allow the liquid to pass through while retaining the solids and fibers. The curved design helps in the dewatering process by allowing the liquid to drain and separate from the solids.

Sieve bend screens offer several advantages in pulp and paper applications, including high efficiency, reliable operation, and the ability to handle high flow rates. They are also durable and resistant to wear, making them suitable for continuous use in demanding industrial environments.

It’s important to note that specific designs and configurations of sieve bend screens can vary depending on the manufacturer and the requirements of the pulp and paper mill. Therefore, it’s recommended to consult with industry experts or manufacturers to determine the most suitable sieve bend screen for a particular application.