Woven wire mesh is a type of wire cloth that is made by weaving individual wires together in a crisscross pattern. The manufacturing process for woven wire mesh typically involves the following steps:

Wire drawing: The first step in the manufacturing process is to draw the wire to the desired diameter. This is done by pulling the wire through a series of dies, which gradually reduce the diameter of the wire.

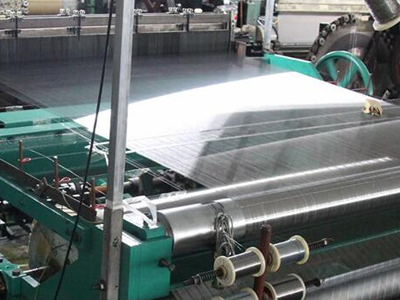

Warping: The next step is to warp the wire onto a loom. This involves winding the wire onto a beam, which is then mounted onto the loom.

Weaving: Once the wire is warped onto the loom, the weaving process can begin. The weft wire is passed over and under the warp wires, creating a crisscross pattern. The weft wire is then beaten down onto the warp wires to create a tight and uniform mesh.

Cutting: Once the mesh is woven, it is cut to the desired size and shape. This is typically done using a cutting machine or shears.

Cleaning and finishing: The final step in the manufacturing process is to clean and finish the mesh. This involves removing any debris or contaminants from the mesh, as well as applying any necessary coatings or finishes.

Overall, the manufacturing process for woven wire mesh is relatively straightforward, but requires precision and attention to detail to ensure that the mesh is strong, durable, and able to withstand the rigors of its intended application. The specific details of the manufacturing process may vary depending on the type of wire mesh being produced and the requirements of the application.