The relationship between woven spacing, opening size, and wire diameter in woven wire mesh is interdependent and can vary based on the specific weave pattern and mesh construction. Here are some general guidelines:

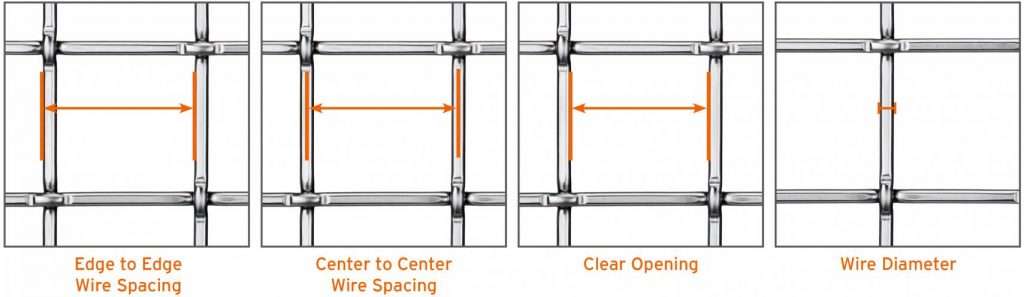

Woven Spacing (Center-to-Center Distance):

The woven spacing, also known as center-to-center distance or pitch, refers to the distance between adjacent wires in the mesh. It determines the openness of the mesh and affects factors such as transparency, airflow, and particle retention. Generally, the woven spacing is larger than the wire diameter.

Opening Size:

The opening size of woven wire mesh refers to the size of the individual openings or apertures formed by the intersecting wires. It is typically measured as the clear distance between two adjacent wires. The opening size is influenced by the woven spacing and wire diameter.

Wire Diameter:

Wire diameter refers to the thickness or gauge of the wires used in the mesh. It plays a crucial role in determining the strength, stability, and durability of the woven wire mesh. The wire diameter affects the opening size and woven spacing of the mesh.

In general, the relationship between woven spacing, opening size, and wire diameter can be described as follows:

Larger wire diameter: A larger wire diameter will typically result in larger opening sizes and wider woven spacing. This is because thicker wires require more space between them, resulting in larger openings in the mesh.

Smaller wire diameter: Smaller wire diameter will generally result in smaller opening sizes and narrower woven spacing. Thinner wires allow for closer placement, resulting in smaller openings in the mesh.

It’s important to note that the relationship between these parameters can vary based on the specific weave pattern, such as plain weave, twill weave, or Dutch weave, as each weave has its own characteristic construction and resulting mesh properties.

When selecting woven wire mesh for a specific application, it’s essential to consider the desired opening size, woven spacing, and wire diameter in relation to the intended purpose of the mesh, such as filtration, separation, or containment requirements.