Knitted wire mesh can be classified into two main types based on the number of strands used in its construction: single strand and multi-strand.

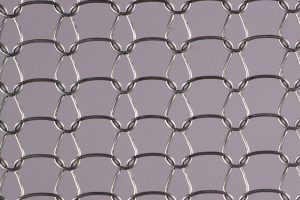

Single Strand Knitted Wire Mesh: In single strand knitted wire mesh, a single continuous wire is used to create the interlocking loops. This type of mesh is typically made by knitting a wire around a series of needles in a circular or flat pattern. Single strand knitted wire mesh offers excellent flexibility and conformability, making it suitable for applications requiring compressibility and resilience. It is commonly used in applications such as filtration, gaskets, seals, protective sleeving, and noise reduction.

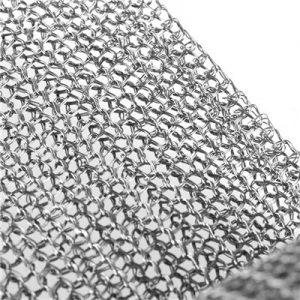

Multi-Strand Knitted Wire Mesh: Multi-strand knitted wire mesh is constructed using multiple strands of wire intertwined together to form the loops. The number of strands can vary, depending on the specific application requirements. Multi-strand knitted wire mesh provides enhanced strength, stability, and higher flow capacity compared to single strand mesh. It is often used in applications where higher tensile strength or structural support is needed, such as industrial filtration, separation processes, heat transfer, and support media for catalysts.