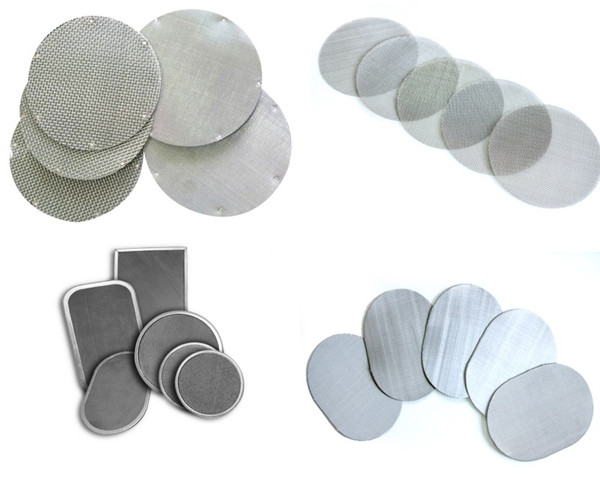

There are several types of filter discs available, each designed for specific filtration applications. Some common types of filter discs include:

Wire Mesh Filter Discs: These filter discs are made of woven wire mesh, typically stainless steel or other corrosion-resistant materials. They are known for their durability and excellent filtration capabilities. Wire mesh filter discs are available in various mesh sizes and can effectively filter out solid particles of different sizes.

Sintered Filter Discs: Sintered filter discs are manufactured by sintering together metal powders or particles to form a porous structure. This process creates a robust and uniform filter media with precise filtration ratings. Sintered discs offer high dirt-holding capacity and can withstand high-pressure differentials.

Pleated Filter Discs: Pleated filter discs feature a pleated or folded filter media, which provides a larger filtration area within a compact space. These discs offer high filtration efficiency, longer service life, and increased dirt-holding capacity compared to flat filter discs. Pleated discs are commonly used in applications where a high flow rate and extended filtration performance are required.

Perforated Filter Discs: Perforated filter discs are made of a solid metal sheet with evenly spaced holes or perforations. They are effective in filtering larger particles or debris from liquids or gases. The size and pattern of the perforations can be customized based on specific filtration requirements.

Wedge Wire Filter Discs: Similar to wedge wire screening, wedge wire filter discs use wedge-shaped wires to create a filtering surface. They are commonly used for fine filtration applications, such as separating solids from liquids or filtering particles of varying sizes.

It’s important to select the appropriate filter disc based on the specific filtration requirements, such as desired filtration efficiency, particle size, flow rate, compatibility with the filtered media, and operating conditions.