Battery expanded and perforated metal mesh are two types of materials commonly used in the manufacturing and design of batteries. While they serve different purposes, both types of mesh play important roles in battery construction and performance. Here’s an overview of battery expanded and perforated metal mesh:

Battery Expanded Metal Mesh:

Battery expanded metal mesh refers to a metal sheet that has been processed to create a pattern of diamond-shaped openings, similar to the expanded metal described earlier. However, in the context of batteries, the expanded metal mesh is specifically designed for use as a grid or support structure within the battery.

The expanded metal mesh serves as a framework that holds the active materials of the battery, such as electrodes and electrolytes. It provides structural integrity, electrical conductivity, and facilitates the flow of ions or electrons within the battery. The mesh is often made from metals like lead, nickel, or their alloys, which offer good conductivity and chemical stability.

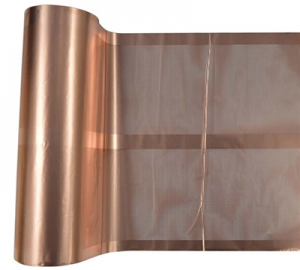

Battery Perforated Metal Mesh:

Battery perforated metal mesh, on the other hand, consists of a metal sheet with regularly spaced holes or perforations. These holes can be round, square, or a custom shape, depending on the specific battery design and requirements.

Perforated metal mesh is primarily used in battery applications for the following purposes:

- Ventilation: Battery cells generate heat during operation, and proper ventilation is essential to dissipate heat and maintain optimal operating temperatures. Perforated metal mesh allows airflow within the battery, facilitating heat dissipation and preventing excessive temperature build-up.

- Gas Diffusion: In some battery chemistries, gases are generated during the charging and discharging processes. The perforations in the metal mesh enable the diffusion of these gases, preventing the accumulation of gas pockets that can adversely affect battery performance and safety.

- Electrolyte Flow: Perforated metal mesh can also be used in batteries with liquid electrolytes. The perforations allow the free flow of electrolyte between the battery compartments, ensuring uniform distribution and facilitating efficient electrochemical reactions.

The selection of battery expanded and perforated metal mesh depends on factors such as the battery type, size, chemistry, and specific performance requirements. Manufacturers and designers of batteries choose the appropriate mesh types to optimize structural integrity, electrical conductivity, ventilation, gas diffusion, and electrolyte flow within the battery system.

It’s worth noting that battery designs and materials can vary significantly across different battery technologies (e.g., lead-acid, lithium-ion, nickel-cadmium), and the specific mesh requirements may differ accordingly.