Knitted mesh demister pads, also known as mist eliminators or mist coalescers, are used in various industries to separate liquid droplets from gas or vapor streams. Here is a description of the processing steps involved in manufacturing knitted mesh demister pads:

Material Selection: Choose a suitable material for the demister pad based on the operating conditions and the desired separation efficiency. Stainless steel is commonly used due to its corrosion resistance, durability, and high mechanical strength.

Wire Selection: Determine the wire diameter and material grade based on the demister pad specifications. Thicker wires are generally used for higher strength and rigidity, while thinner wires provide a larger surface area for droplet capture. The wire diameter also affects the mesh density and pressure drop across the demister pad.

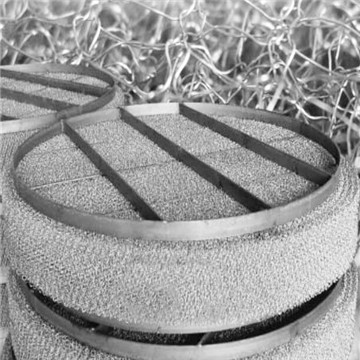

Knitting Process: Knitted mesh demister pads are manufactured using specialized knitting machines. The knitting process involves interlocking the wires in a specific pattern to create a mesh structure with uniform openings. The knitting machines are equipped with needles, sinkers, and guide bars that control the movement of the wires to form the desired mesh pattern.

Sizing and Shaping: The knitted mesh is cut and shaped to the required dimensions for the demister pad. This can involve trimming the edges to achieve the desired shape and size, such as circular, rectangular, or custom shapes to fit specific equipment or vessels.

Frame Assembly (Optional): Depending on the application, the knitted mesh demister pad may be installed within a supporting frame. The frame provides structural support and facilitates the installation and removal of the demister pad. Frames can be made of materials like stainless steel or polypropylene.

Inspection and Quality Control: The knitted mesh demister pads undergo thorough inspection to ensure they meet the required specifications. This includes visual inspections for any defects or irregularities in the mesh, measurement of wire diameter and mesh density, and quality control checks to ensure the overall performance and efficiency of the demister pad.

Packaging and Delivery: Once the knitted mesh demister pads pass the quality control checks and any additional surface treatments, they are properly packaged to protect them during transportation. The demister pads are typically shipped to the customers along with any necessary installation instructions or documentation.