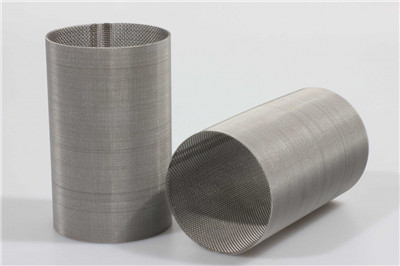

Woven mesh tube processing refers to the manufacturing and fabrication techniques used to create tubes or cylinders from woven wire mesh. Woven wire mesh is a material composed of interlaced metal wires that form a grid pattern. The processing of woven mesh tubes involves several steps, including material selection, cutting, shaping, and joining.

Material Selection: The first step in woven mesh tube processing is selecting the appropriate type of woven wire mesh for the desired application. The choice of material depends on factors such as the intended use, environmental conditions, and required properties (e.g., strength, corrosion resistance).

Cutting: Once the material is selected, the woven wire mesh is cut into the desired length. This can be done using various methods, including shearing, laser cutting, or water jet cutting, depending on the thickness and type of mesh.

Shaping: After cutting, the flat mesh sheet is shaped into a cylindrical form to create the tube. This can be accomplished through various techniques, such as rolling the mesh and joining the edges or bending the mesh around a mandrel to form a seamless tube.

Joining: The edges of the woven wire mesh are joined together to create a continuous tube. The joining method can vary depending on the type of mesh and the intended application. Common joining techniques include welding, soldering, or using mechanical fasteners.

Finishing: Once the woven mesh tube is formed and joined, it may undergo additional finishing processes. These processes can include surface treatments like cleaning, deburring, or polishing to enhance the appearance and remove any sharp edges.

Applications of woven mesh tubes can be found in various industries, including filtration, separation, fluid handling, heat transfer, and protection. The unique properties of woven wire mesh, such as high strength, durability, and the ability to control particle size, make woven mesh tubes suitable for applications that require precise filtration, fluid flow control, or protection against debris or insects.