Sieve bend screen processing involves the manufacturing and fabrication techniques used to create curved screens known as sieve bends. Sieve bend screens are widely used in industries such as mining, aggregate processing, wastewater treatment, and food processing. They are primarily used for classification, dewatering, and solid-liquid separation applications. The processing of sieve bend screens includes several steps, such as material selection, wire profiling, welding, forming, and finishing.

Material Selection: The first step in sieve bend screen processing is selecting the appropriate material for the screen based on the application requirements. Common materials used for sieve bend screens include stainless steel, carbon steel, and other corrosion-resistant alloys, depending on the compatibility with the material being processed and the operating conditions.

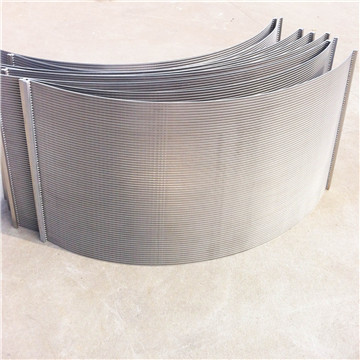

Wire Profiling: In this step, individual wires are shaped into a specific profile to create the curved screen surface. The profiling process involves precision cutting and shaping of the wire to achieve the desired curve and slot opening size. The profiled wires are typically V-shaped or wedge-shaped.

Welding: The profiled wires are then welded to support rods to form a continuous and rigid structure. The support rods are usually placed perpendicular to the profiled wires and provide structural integrity to the sieve bend screen.

Forming: After the welding process, the welded profiled wire elements are formed into the curved shape to create the sieve bend screen. This can be achieved by using specialized machinery or bending equipment that can accurately shape the screen to the desired radius or curvature.

Finishing: After forming the sieve bend screen, it may undergo additional finishing processes. This can include surface treatments such as cleaning, deburring, or polishing to remove any sharp edges or surface imperfections. The screen may also be coated or plated to enhance corrosion resistance, improve surface characteristics, or meet specific industry standards.