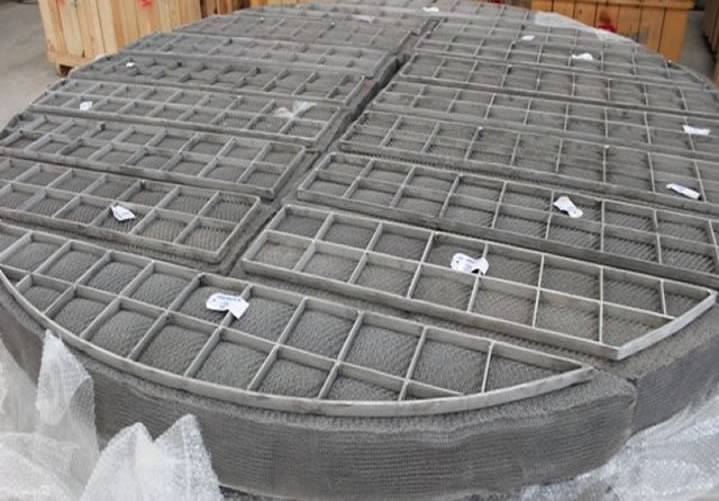

Ease of installation: Large demister pads can be challenging to install in a single piece, especially in equipment with limited access or tight spaces. By dividing the demister pad into smaller segments, it becomes more manageable to handle and install. The segmented design allows for easier maneuverability during installation, even in complex or confined spaces.

Flexibility and adaptability: Segmented demister pads offer flexibility in adapting to non-uniform or irregularly shaped equipment internals. The individual segments can be adjusted and positioned independently to fit the specific contours and dimensions of the vessel or column. This ensures a proper fit and maximizes the coverage of the mist removal area.

Maintenance and replacement: Segmented demister pads simplify maintenance and replacement procedures. If one segment of the demister pad becomes damaged, clogged, or requires replacement, only that specific segment needs to be addressed, minimizing downtime and cost. It allows for targeted maintenance or replacement without disturbing the entire demister pad assembly.

Manufacturing and transportation: Segmented demister pads can be manufactured in smaller sections, making them more feasible for production and transportation. It may be more efficient and cost-effective to produce and ship smaller segments compared to a single large demister pad. This benefits both manufacturers and end-users in terms of logistics and cost.