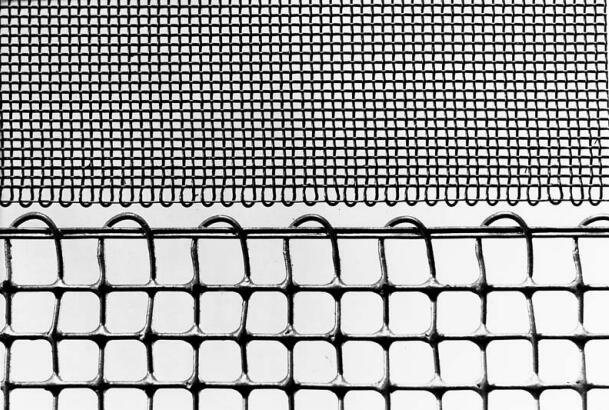

The selvage edge of a woven wire mesh refers to the finished edge of the mesh that runs parallel to the warp wires. It is created by looping the weft wire around the last warp wire at the edge of the mesh, which creates a secure and durable edge that prevents the mesh from unraveling or fraying.

The selvage edge of a woven wire mesh is an important aspect of the manufacturing process, as it ensures that the mesh is strong and durable enough to withstand the rigors of its intended application. The selvage edge also provides a clean and finished look to the mesh, which is important for aesthetic and functional purposes.

There are several different types of selvage edges that can be used in woven wire mesh, including:

Loop selvage: This is the most common type of selvage edge, and is created by looping the weft wire around the last warp wire and then back through the mesh. This creates a looped edge that is strong and durable.

Welded selvage: This type of selvage edge is created by welding the weft wire to the last warp wire at the edge of the mesh. This creates a strong and durable edge that is resistant to fraying and unraveling.

Knuckled selvage: This type of selvage edge is created by bending the weft wire back on itself at the edge of the mesh, creating a knuckle-like shape. This creates a strong and durable edge that is resistant to fraying and unraveling.

Overall, the selvage edge of a woven wire mesh is an important aspect of the manufacturing process that ensures the mesh is strong, durable, and able to withstand the rigors of its intended application. The type of selvage edge used will depend on the specific requirements of the application, as well as the preferences of the manufacturer.