Choosing between plain woven mesh and twill woven mesh depends on several factors, including the specific application requirements and desired characteristics. Here are some key considerations to help you make an informed decision:

Weave Pattern: Plain woven mesh and twill woven mesh have different weave patterns, which result in distinct properties and appearances.

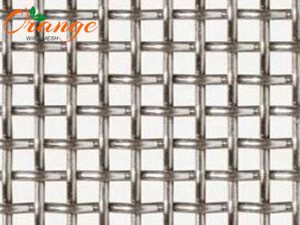

Plain weave: Each warp wire passes across the top and bottom of each weft to form a 90 degree. The warp and weft wire applied have the same diameter.

Twill weave: Each warp wire passes across in the top and bottom of each two weft wire, each weft wire passes across each two warp wire up and down.

Filtration or Separation Requirements: Consider the desired filtration or separation efficiency for your application. Plain woven mesh typically offers a more uniform opening size, making it suitable for precise filtration where fine particles need to be separated. Twill woven mesh, with its diagonal pattern, can be more effective in retaining larger particles or allowing for better flow in certain applications.

Material Compatibility: Both plain woven mesh and twill woven mesh are available in various materials, such as stainless steel, galvanized steel, or other alloys. Consider the material properties, including corrosion resistance, temperature resistance, and chemical compatibility, to select a mesh that is suitable for the specific application environment.

Aesthetic Preferences: If the appearance is a significant factor, consider the visual aesthetics of the weave pattern. Plain woven mesh provides a clean and symmetrical appearance, while twill woven mesh offers a more textured and diagonal pattern, which may be preferred for certain architectural or design applications.

Wire Diameter and Mesh Opening Size: Evaluate the wire diameter and mesh opening size requirements for your application. Depending on the specific weave pattern, the relationship between wire diameter and mesh opening size can differ between plain woven mesh and twill woven mesh.